SKEDSOFT

Introduction:

Vehicle transmissions require devices to match the ratio, and thus the power avail-able, to the prevailing driving conditions. “Power matching” is one of the four main functions of a vehicle transmission. In manual gearboxes, changing gear is controlled and carried out by the driver. Depending on the amount of automation, in all other gearboxes electronics and actuator systems take over this function partially or completely. Certain transmission functions, such as Neutral, Reverse, and Park are however still controlled by the driver using a shifting device.

Gear shifting:

- The gear shifting mechanism thus plays an important role in the interface be-tween driver and vehicle. Its handling has a major influence on perceived comfort.

- The components used in a gear shifting mechanism depend largely on whether shifting gear involves interrupting the power flow.

- Other factors are the type of vehicle (passenger car or truck), the type of drive (front-wheel or rear-wheel drive) and the operating conditions.

Shifting Elements for Transmissions with Power Interruption

Shifting by hand entails more than bringing gearwheels into the power flow. An exact and smooth-running operation of the gearshift lever is needed. This involves the interaction of external shifting with internal shifting elements.

Internal Gearshift Systems for Manual and Automated Transmissions:

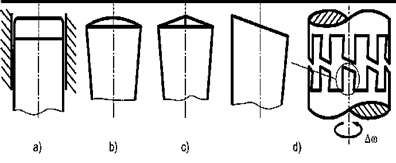

Figure shows Dog shapes in unsynchronized mechanisms.(a)Fuller dog; (b) ZF dog; (c) Berliet dog; (d) deflector dog (Maybachoverride dog): as long as there is relative movement, the bevelled deflector surfaces prevent engagement.

- The simplest type of shift system is sliding gears.

- The gear wheels are not constantly meshed but are shifted into the power flow as needed.

- Sliding gears are used for reverse gear in both passenger car and commercial vehicle transmissions. Unsynchronized constant-mesh transmissions are often found in commercial vehicle transmissions.

- The constant-mesh gear pairs run on rolling bearings and have a positive locking connection to the transmission shaft via a sliding dog sleeve (gearshift sleeve).

- The gears are prevented from disengaging (gear dropout) by undercut dogs.

- Gearshifting is always made up of a selecting movement and a shifting movement. The selecting movement selects the gearshift sleeve to be shifted, and the shifting movement moves the gearwheel into the power flow

- The gear-shift lever and the ball joint serve to select the gear and transmit the manual effort. The path where the gearshift lever can move a gearshift sleeve is known as the gate. When a gate is selected, the selector finger of the gearshift lever engages in the grooves of one of the individual selector bars

- The selector bar is shifted axially with a longitudinal movement of the gearshift lever, thus changing gear.

External Gearshift Systems for Manual and Automated Transmissions

- Kinematics is needed to describe the breakdown of gear changing into selecting and shifting movements. In order to avoid load changing reactions and vibrations in the gearshift lever and gearshift housing, the external gearshift system is suitably decoupled from the gearbox and the car body.

- The reverse gear is safeguarded against operating errors with a locking device, depending on the philosophy of the vehicle manufacturer.

- The external shifting elements and some of the internal shifting elements of a passenger car with a transverse-mounted gearbox.