SKEDSOFT

Introduction:

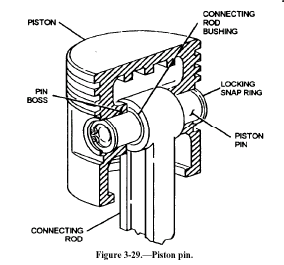

It is provided on the piston. It joins the piston and connecting rod. A piston pin is also known as a wrist pin because of its similarity in construction with human hand and arm joint. Since the piston pin reciprocates with the piston, its weight is minimized by making it hollow, so that the inertia forces at piston TDC are decreased.

Properties of the Piston Pin:

- Hollow polished steel pin.

- Attached in a variety of ways.

- Pinned to piston.

- Clamped to rod small end.

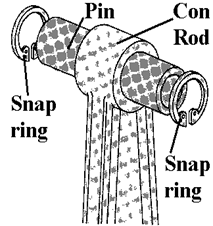

- Snap ring free floating.

- Press fit.

Fig: Piston pin

Materials used for the piston pin:

- Piston pins are made of casehardening steel, either plain carbon steel, nickel steel or chrome-nickel steel.

- The piston pins are designed to work as bearing journals.

Note: While the engine developed quickly and engine performance improved greatly, the demand for engine parts is becoming higher and higher. As an important part in engine, piston endures the cyclic gas pressure and the inertial forces at work, and this working condition may cause the fatigue damage of piston, such as piston side wear, piston pin seat crack and so on.