SKEDSOFT

Introduction:

The function of the compressor is to compress and circulate superheated refrigerant vapour around a closed loop system (any liquid or dirt will damage the compressor). Industrial plants use compressed air throughout their production operations, which is produced by compressed air units ranging from 5 horsepower (hp) to over 50,000 hp. The compressor can only compress refrigerant vapour. Any liquid or dirt allowed to enter the compressor will cause damage.

Types of compressor

There are three main categories of compressor:

1. Reciprocating – crank and axial piston (swash plate).

2. Rotary – vane.

3. Oscillating – scroll type (helix).

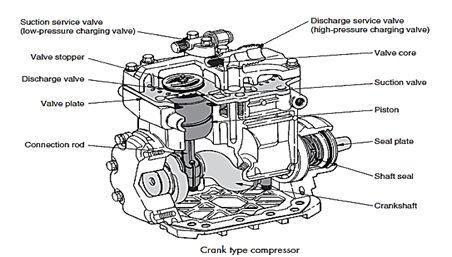

Crank type compressor (reciprocating)

- Crank type compressors are not generally used in the automotive industry any more.

- They may have up to two cylinders including ‘V’ shape configuration. They are driven by the engine pulley system which rotates a crankshaft inside the pump. The

- Crankshaft is connected to a piston via a connecting rod which travels up and down the bore.

- Above the piston there is a valve assembly to direct the flow of refrigerant.

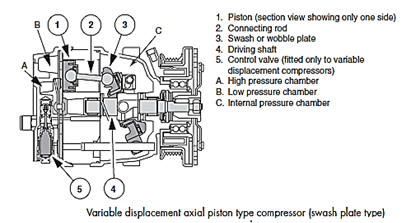

Axial piston (swash plate) type variable capacity compressor

- The axial piston type (is one of the most common types of compressor and can be fixed or variable capacity.

- The pumping cylinders are circumferentially situated around the outside of the drive shaft (4) and parallel to its axis. Each cylinder has a double ended piston with a separate pumping chamber at each end. Each pumping chamber has a set of inlet and discharge reed valves.

Vane type compressor: The vane type compressor is compact and has low frictional losses. It is quiet and has few moving parts. It is a rotary compressor using rotating vanes to increase the flow of refrigerant. There are two types of vane type compressor:

1. through vane.

2. Eccentric vane.

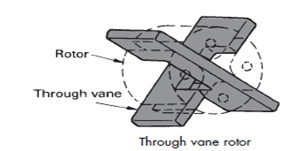

Through vane type rotor

The through vane type has two vanes mounted at right angles to each other in slots in a rotor housing. As the rotor rotates the vanes slide radially to maintain contact with the surface, this is maintained through centrifugal force. The circulating refrigerant oil with the centrifugal force seals the moving parts relative to one another.

Eccentric vane

The eccentric vane works in a similar manner to the through vane except the vanes are organised separately and are not mounted at right angles to each other. The rotor inside the vane compressor rotates on an eccentric which is used to increase and decrease the volume within the compressor.

Scroll (helix) type compressor

The scroll compressor consists of two helices with one lying within the other. They are both mounted in a cylindrical housing. One helix is fixed and the other is attached to the drive shaft of the compressor. The driven helix does not rotate itself but does orbit the other helix. The two helices through movement create crescent-shaped compression chambers.