SKEDSOFT

Introduction:

Some light-duty trucks and sport utility vehicles (SUVs) have torsion bar front suspension systems. These suspension systems have longitudinally mounted torsion bars.

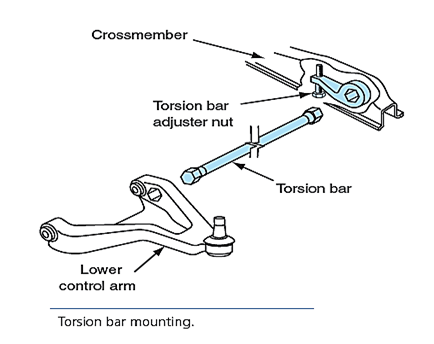

Torsion bar mounting:

- The front and rear ends of the torsion bars have a hex shape.

- The front end of each torsion bar is anchored in the lower control arm and the rear end of the torsion bars is anchored to a chassis cross-member.

- Since the twisting of the torsion bars supports the vehicle weight, the torsion bars replace the coil springs.

- Torsion bar front suspension systems are often used on four-wheel-drive trucks, because the absence of coil springs allows more space for the front drive axles.

- On some torsion bar front suspension systems the torsion bars are anchored into the upper control arms rather than the lower control arms.

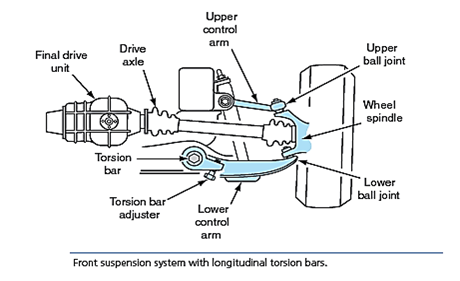

Front suspension system with longitudinal torsion bars:

- Vehicle ride height is controlled by the torsion bar anchor adjusting bolts in the cross-member. Front suspension heights must be within specifications for correct wheel alignment, tire wear, satisfactory ride, and accurate bumper heights.

- A conventional stabilizer bar is connected between the lower control arms and the cross-member. Ball joints are located in the upper and lower control arms, and both ball joints are bolted into the steering knuckle.

- The shock absorbers are connected between the lower control arms and the cross-member support, and the inner ends of the lower control arms are bolted to the cross-member through an insulating bushing.

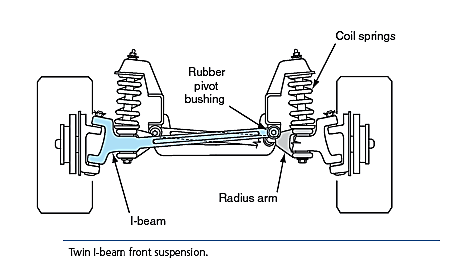

Twin I-Beam Suspension Systems

In this type of suspension system, each front wheel is connected to a separate I-beam. In some I-beam front suspension systems, kingpins are used to attach the I-beams to the spindles. In other I-beam suspension systems, ball joints connect the I-beams to the spindles.