SKEDSOFT

Introduction:

Regular visual inspection of the machinery and systems in a plant is a necessary part of any predictive maintenance program. In many cases, visual inspection will detect potential problems that will be missed using the other predictive maintenance techniques. All equipment and systems in the plant should be visually inspected on a regular basis.

VISUAL INSPECTION METHODS

Generally, visual inspection can be broken into two major classifications: those that can be conducted using only human senses and those that require the use of sensors or instrumentation.

Human Senses

- Humans have a great capability for sensing unusual sights, sounds, smells, tastes, vibrations, and touches. Human senses are able to detect large differences but are generally not sensitive to small changes.

- Time tends to have a dulling effect. Have you ever tried to determine if one color was the same as another without having a sample of each to compare side by side? If you have, you will understand the need for standards. A standard is any example that can be compared to the existing situation as a measurement.

- Quantitative specifications, photographs, recordings, and actual samples should be provided.

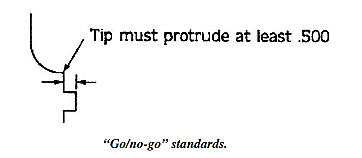

- The critical parameters should be clearly marked on the samples with display as to what is good and what is bad. It is best if judgments can be reduced to “go/no-go.”

Sensors

- Because humans are not continually alert or sensitive to small changes and cannot get inside small spaces, especially when operating, it is necessary to use sensors that measure conditions and transmit information to external indicators.

- Sensor technology is progressing rapidly; considerable improvements have been made in capability, accuracy, size, and cost.

- Pressure transducers, temperature thermocouples, electrical ammeters, revolution counters, and a liquid height-level float are examples found in most automobiles.

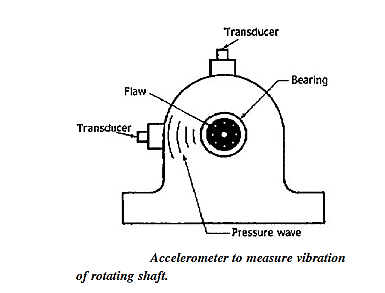

- Accelerometers, eddy-current proximity sensors, and velocity seismic transducers are enabling the techniques of motion, position, and expansion analysis to be increasingly applied to large numbers of rotating equipment. Motors, turbines, compressors, jet engines, and generators can use vibration analysis.

Spectrometric Oil Analysis

- The spectrometric oil analysis (SOA) process is useful for any mechanical moving device that uses oil for lubrication. It tests for presence of metals, water, glycol, fuel dilution, viscosity, and solid particles.

- Automotive engines, compressors, and turbines all benefit from oil analysis. Most major oil companies provide this service if you purchase lubricants from them.

- Experience indicates that the typical result is that less oil is used and costs are reduced from what they were before using SOA.

- The major advantage of SOA is early detection of component wear.

- Not only does it evaluate when oil is no longer lubricating properly and should be replaced, but it also identifies and measures small quantities of metals that are wearing from the moving surfaces.