SKEDSOFT

application of ultrasonics: Ultrasonic waves have a wide range of applications in various fields e.g., engineering, medical, metallurgical, physical, chemical, etc. Some of their uses are discussed in below..

Ultrasonic Drilling and Cutting:

Ultrasonic are used for making holes in very hard materials such as glass, diamond etc., When ultrasonic are passed through these materials it creates air bubbles. This air bubbles collapses within short span of time, thereby a larger amount of pressure and temperature which are used for cutting and drilling.

Ultrasonic Cleaning:

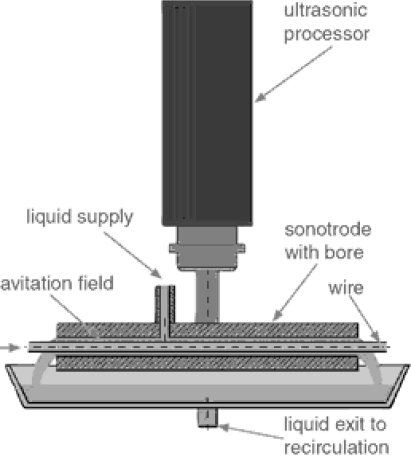

Ultrasonic cleaning is an environmentally friendly alternative for the cleaning of continuous materials, such as wire and cable, tape or tubes. The effect of the cavitations generated by the ultrasonic power removes lubrication residues like oil or grease, soaps, stearates or dust. In addition, the pollution particles are dispersed into the cleaning liquid. By that, a new adhesion to the material to be cleaned is avoided and the particles are flushed away. By the use of an innovative proprietary ultrasonic technology, very strong cavitations fields are generated, so that very good cleaning results at high line speeds can be accomplished. As the cleaning effect is based on the physical cleaning effects of the ultrasound, it can be used for any ferrous and non-ferrous material, e.g. stainless steel, copper, aluminum, but also plastic or

glass. Most commonly ultrasonic cleaning machines are used for drawn wire, e.g. before cladding or extrusion. By the concentration of the ultrasonic power to a low liquid volume, a very compact design can be realized. This can be easily integrated into existing or new production lines, e.g. directly after drawing or reel payoff.

Cavitation is an effect that is generated in liquids by intensive ultrasonic waves. The resulting pressure waves create vacuum bubbles that implode subsequently. As a result of these implosions, very high pressures and temperatures occur in combination with liquid jets of up to 1000km/h. At surfaces, these mechanical forces loosen impurities, so they can be flushed away with the cleaning liquid. For an intensive cavitation - and by that for an intensive cleaning - high amplitudes and a low ultrasonic frequency (approx. 20 kHz) are needed. Ultrasonic Cleaners are used in various industries for a number of applications.