SKEDSOFT

Example: (Wire Harness Inspection Issues)

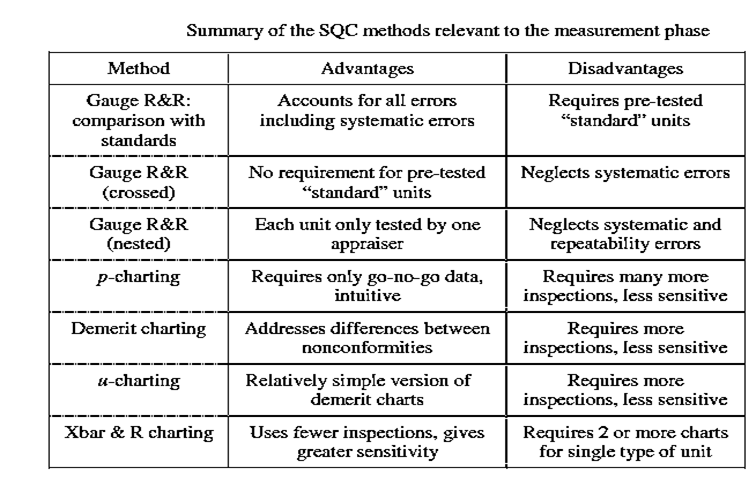

A wire harness manufacturer discovers voids in the epoxy that sometimes requires rework. A team trying to reduce the amount of rework fined that the two inspectors working on the line are applying different standards. Team experts carefully inspect ten units and determine trustworthy void counts. What technique would you recommend for establishing which inspector has the more appropriate inspection method?

Answer: Since the issue is systematic errors, the only relevant method is comparison with standards. Also, this method is possible since standard values are available.

- In the context of six sigma projects, statistical process control charts offer thorough evaluation of system performance. This is relevant both before and after system inputs are adjusted in the measure and control or verify phases respectively.

- For example, values of p, u, or R consistently below the lower control limits after the improvement phase settings are implemented indicate success. Therefore, it is often necessary to go through two start-up phases in a six sigma project during

- the measure phase and during the control or verify phase. Hopefully, the established process capabilities, sigma levels, and/or Cpknumbers will confirm improvement and aid in evaluation of monetary benefits.

Example (Printed Circuit Board System Evaluation)

A team has a clear charter to reduce the fraction of nonconforming printed circuit boards requiring rework. A previous team had the same charter but failed because team members tampered with the settings and actually increased the fraction nonconforming. What next steps do you recommend?

Answer: Since there apparently is evidence that the process has become worse, it might be advisable to return to the system inputs documented in the manufacturing SOP prior to interventions by the previous team. Then, measurement systems should be evaluated using the appropriate gauge R&R method unless experts are confident that they should be trusted. If only the fraction nonconforming numbers are available, p-charting should be implemented to thoroughly evaluate the system both before and after changes to inputs.