SKEDSOFT

Introduction:

There are two different types of ‘checks’ in the quality improvement cycle (the PDCA cycle).

Do phase:

- In the ‘do phase’ of the PDCA cycle there are usually some standards (standard operations) which must be followed.

- These constraints consist of restrictions which must be adhered to in performing the work; items which ensure the safety of employees or assure product quality are the most important of these.

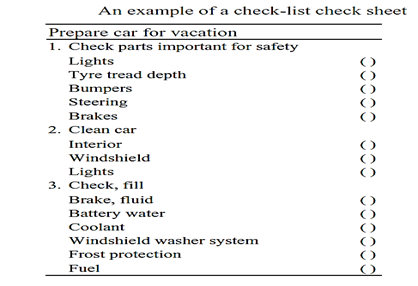

- To ensure adherence it is advisable to design a check-list check sheet with the constraints (‘must-be operations’) listed. During the process the operator has to document that all the must-be operations have been followed.

- The documentation may be the signature of the operator or an ‘OK mark’ for each operation listed and a signature at the end of the check-list.

- It is a good idea that the operators are educated, trained and motivated to use such a check-list check sheet.

Check phase:

- The second type of ‘check’ during the PDCA cycle is done in ‘the check phase’.

- Here the results are compared with the plan and the causes behind any significant gaps are identified and studied. The keywords here are study, learn and understand variations.

- If, and only if, the variations are understood it is possible to continue the rotation of the PDCA cycle in an efficient way.

- But profound understanding is only possible if meaningful data is available and meaningful data will only be available if it has been well planned.

- In the plan phase of the PDCA cycle the necessary data collection must be planned so that the collection can be done in the do phase and so that the necessary data analysis can be done in the check phase.

- In order to carry out the data collection and analysis effectively it is a good idea to design a check sheet which simplifies the whole process.

- Such a check sheet must be specifically designed for each PDCA application because the need for data varies from application to application.

- As a rule of thumb check sheets need both ‘result data’ and ‘cause data’.

- Examples of result data are number of defects/failures, production size or inspection size. Examples of cause data come from ‘the six Ms’ (men, machines, materials, methods, management).