SKEDSOFT

Introduction:

Implementation of TPM is approached differently by manufacturing organisations. The implementation of a comprehensive TPM programme has to be a top down approach.

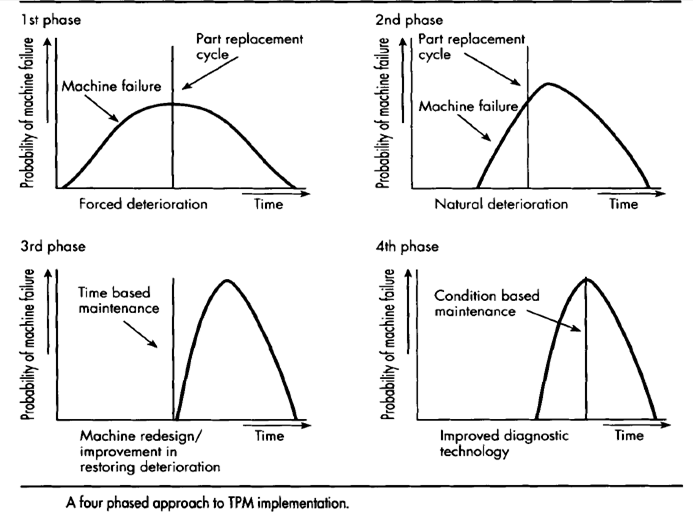

A four phased approach toTPM implementation:

TPM has to be a boardroom activity considered for its power to add value to organisational activities by helping meet customer requirements and achieving set objectives.

Stages in implementation of TPM:

The corporate place

- Total Preventative Maintenance has to be initiated and encouraged by top management.

- Its role has to be perceived not only in determining process capability but also in maintaining process stability so that customer requirements are met first time and every time.

- Unless true process capability is known, it will be hard for any organisation to set future objectives.

- Total Preventative Maintenance interacts with key activities within the organisation, such as design (design for manufacturability through good knowledge of process capability) and operations (planning, scheduling and control are closely related to capacity availability).

- Its appreciation at the corporate level has, therefore, got to be followed by high levels of commitment and the allocation of adequate resources and means.