SKEDSOFT

Introduction:

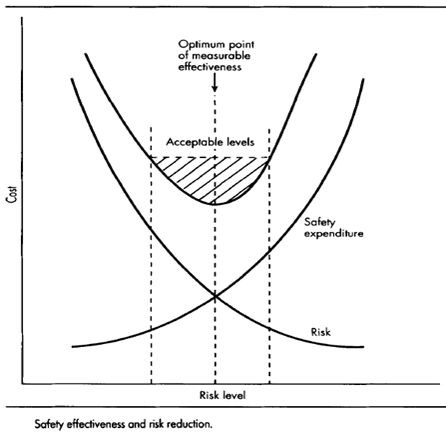

A safety strategy for TQM success would however place emphasis on risk elimination (Zero Risk) rather than risk minimization. One would find that there will be an optimum point where expenditure on safety would be most effective after which, other factors have to be considered before further improvements can take place.

Safety effectiveness and risk reduction:

- It is quite feasible that some of the risks will never be eliminated or would require a long term effort before they are completely removed.

- It is therefore more feasible to adopt a strategy of containment/improvement for certain risks.

- There is a similar analogy to process capability and the impact of random variables.

- One would therefore find that there will be an optimum point where expenditure on safety would be most effective after which; other factors have to be considered before further improvements can take place.

- It may be difficult or it would require longer to raise high safety standards to a higher level (because of economic viability, business/operational or structural constraints), lower standards are easily identifiable because at that point risks are at an optimum level.

- Any slippage results in disastrous consequences for the organisations concerned.

Business economics and safety standards:

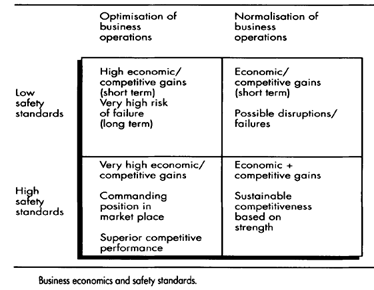

The relationship between expenditure on safety (i.e. the establishment of safety standards) and economic gains via optimization of business operations is better explained by the matrix.

Quadrant 1:A low consideration of safety standards at the detriment of maximizing short term economic gains means high and persisting levels of risk.

Quadrant 2:Even if the intention is to run business operations under normal conditions without seeking to optimize output, low safety consideration still means that there are risks of failure.

Quadrant 3:There is a strong correlation between the establishment of high safety standards/optimization of operations and the level of competitiveness. If companies strive for excellence in every aspect, superior performance can be achieved by the development of Zero Risk, Zero Defect strategy.

Quadrant 4:This is perhaps a more realistic option where on the one hand optimization of operations is closely determined by process capability and safety standards are improved upon through a continuous improvement programme.