SKEDSOFT

The Japanese Zaibatsu model:

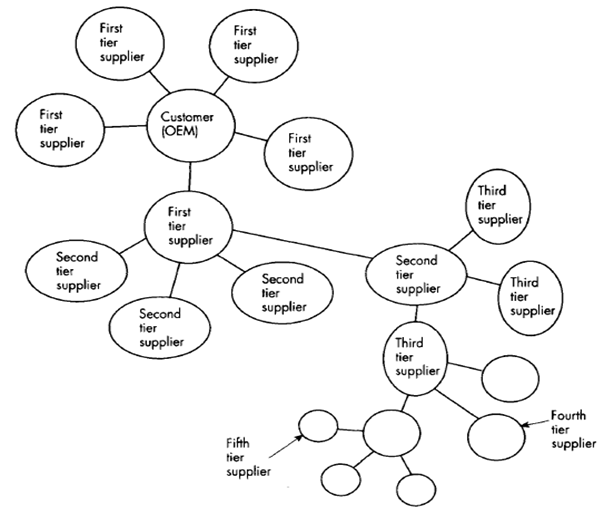

The Japanese Zaibatsu model assumes that there is a strong relationship between a customer (Original Equipment Manufacturer) and a supplier company (first tier). The latter manage their own relationships with their suppliers with whom they have established long term partnerships (second tier) and so on. It is anticipated under this arrangement that no changes at all take place at the first tier level where the ties are strong. Any changes that take place occur at the second or third tiers. The customer (Original Equipment Manufacturer) may have direct dealings with second tier suppliers.

The Zaibatsu approach to managing customer - supplier chains:

A study which compared the Japanese approach towards customer-supplier chains based on the Zaibatsu model and the American approach of establishing customer supplier chains has concluded that there are nine main criteria which facilitate the creation of strong customer-supplier chains based on single sourcing. These include the following:

- Well defined mandates, goals and objectives: The responding companies seemed to have clear ideas of what they were expected to do;

- Focused customers: Optimized outsourcing to reduce fixed costs and to enable better communications, co-ordination and compatibility of JIT philosophies;

- Supplier aggressiveness: Tight profit margins mean that suppliers have to optimize production efficiency and economies of scale so that prices are reduced further;

- User/producer interface: Co-operation and involvement at various stages of the product development process. Use joint task forces to tackle problems together so suppliers get a good understanding of customer's production processes;

- Selection of suppliers based on equipment compatibility: Synchronization of production processes between suppliers and customers. Supplier equipment capability and compatibility is often the issue rather than price;