SKEDSOFT

Introduction:

Statistical Quality Control (SQC) is used to measure the degree of conformance of raw materials, processes and products to previously agreed specifications.Statistica1 quality control (SQC) is the term used to describe the set of statistical tools used by quality professionals.

Categories of SQC:

Quality control can be divided into three broad categories:

1. Descriptive statistics are used to describe quality characteristics and relationships. Included are statistics such as the mean, standard deviation, the range, and a measure of the distribution of data.

2. Statistical process control (SPC) involves inspecting a random sample of the output from a process and deciding whether the process is producing products with characteristics that fall within a predetermined range. SPC answers the question of whether the process is functioning properly or not.

3. Acceptance sampling is the process of randomly inspecting a sample of goods and deciding whether to accept the entire lot based on the results. Acceptance sampling determines whether a batch of goods should be accepted or rejected.

Charts:

- It uses X and R charts for measuring variations (e.g. weight, dimensions).

- An X chart is used for plotting the average reading against control limits.

- The range (R) chart plots the difference between the largest and smallest reading.

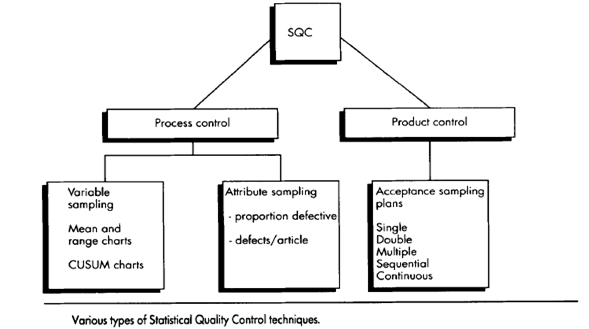

- Statistical Quality Control techniques can therefore be classified into two groups: those concerned with process control and those dealing with the control of variables.