SKEDSOFT

Introduction:

The automobile engine connecting rod is a high volume production, critical component. It connects reciprocating piston to rotating crankshaft, transmitting the thrust of the piston to the crankshaft. Every vehicle that uses an internal combustion engine requires at least one connecting rod depending upon the number of cylinders in the engine.

Manufacturing Connecting Rod:

- Connecting rods for automotive applications are typically manufactured by forging from either wrought steel or powdered metal.

- They could also be cast.

- However, castings could have blow-holes which are detrimental from durability and fatigue points of view. The fact that forgings produce blow-hole-free and better rods gives them an advantage over cast rods.

- Between the forging processes, powder forged or drop forged, each process has its own pros and cons. Powder metal manufactured blanks have the advantage of being near net shape, reducing material waste.

- Bringing the part to final dimensions under tight tolerance results in high expenditure for machining, as the blank usually contains more excess material.

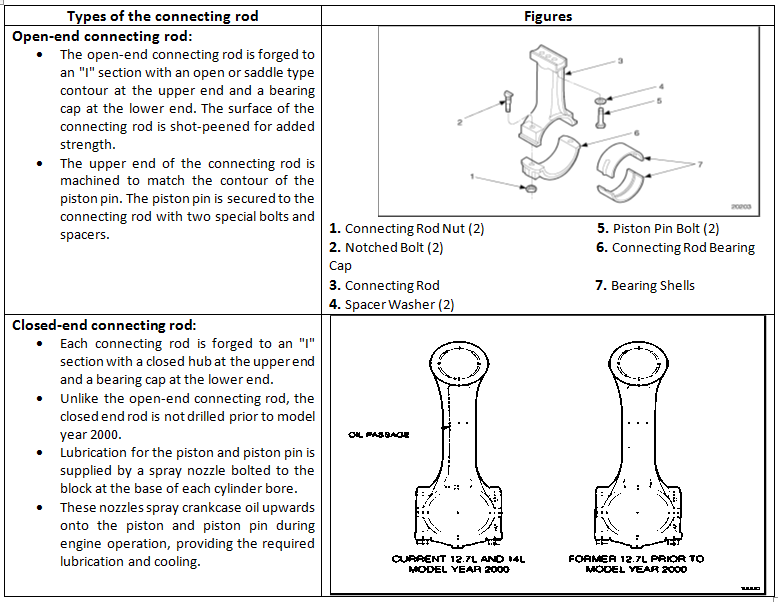

Types of the connecting rod two types of connecting rod are used in Series 60 engines: