SKEDSOFT

Introduction:

On all modern manual lever change (shift) gearboxes, the selection of different ratios is achieved by locking gears to the main shaft.

Gear ratio selection:

- On all modern manual change (shift) gearboxes, the selection of different ratios is achieved by locking gears to the main shaft. A synchromesh and clutch mechanism does this when moved by a selector fork.

- The selector fork is moved by a rod, or rail, which in turn is moved by the external mechanism and the gearstick.

- To save space, some manufacturers use a single selector shaft.

- This means the shaft has to twist and move lengthways. The twisting allows a finger to contact with different selector forks.

- The lengthways movement pushes the synchronizers into position. All selector forks are fitted on the same shaft.

Gear shift or selector fork: 1, shift fork; 2, fluid guide edge (for lubrication); 3, fluid baffle

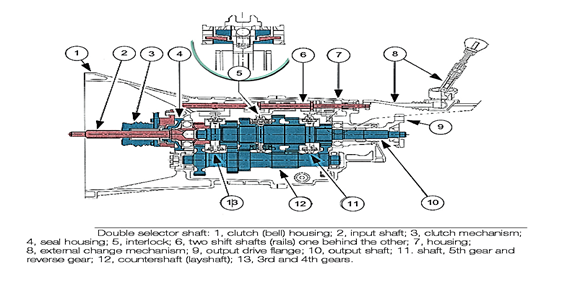

DOUBLE SELECTOR SHAFT:

- On a two-shaft system, the main selector shaft often operates the first/second gear selector fork.

- An auxiliary shaft operates the third/fourth selector fork

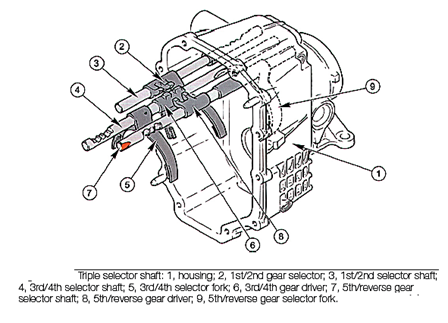

TRIPLE SELECTOR SHAFT:

- The three-rail, or three-shaft system, is similar to the two-shaft type.

- However, each individual shaft can be moved lengthways.

- In turn, the shafts will move the first/second, third/fourth or fifth/reverse forks.