SKEDSOFT

Introduction:

A transmission system gearbox is required because the power of an engine consists of speed and torque. Torque is the twisting force of the engine’s crankshaft and speed is its rate of rotation.

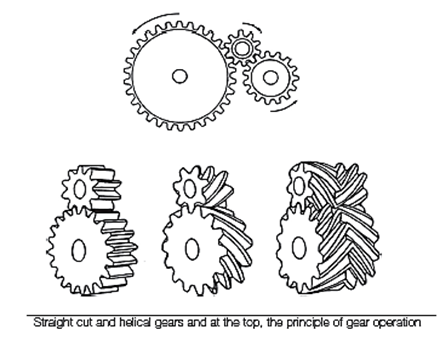

THE PRINCIPLE OF GEAR OPERATION

- The transmission can adjust the proportion of torque and speed that is delivered from the engine to the drive shafts.

- When torque is increased, speed decreases, and when speed is increased, the torque decreases.

- The transmission also reverses the drive and provides a neutral position when required.

- Helical gears are used for almost all modern gearboxes. They run more smoothly and are quieter in operation.

- Earlier sliding-mesh gearboxes used straight-cut gears, as these were easier to manufacture.

- Helical gears do produce some sideways force when operating, but this is dealt with using thrust bearings.

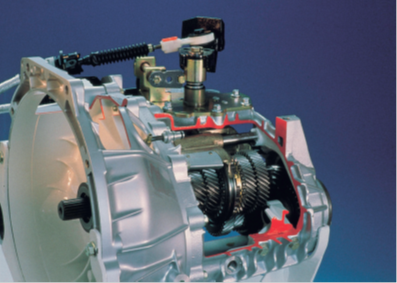

FRONT-WHEEL DRIVE GEARBOX:

- For most light vehicles, a gearbox has five forward gears and one reverse gear. It is used to allow operation of the vehicle through a suitable range of speeds and torque.

- A manual gearbox needs a clutch to disconnect the engine crankshaft from the gearbox while changing gears.

- The driver changes gears by moving a lever, which is connected to the box by a mechanical linkage.

- Alternatively, gears can be changed by electrohydraulic methods in response to paddle switches located behind the steering wheel.

- The gearbox converts the engine power by a system of gears, providing different ratios between the engine and the wheels.

- When the vehicle is moving off from rest, the gearbox is placed in first, or low gear.

- This produces a high torque but low wheel speed. As the car speeds up, the next higher gear is selected. With each higher gear, the output turns more quickly but with less torque.

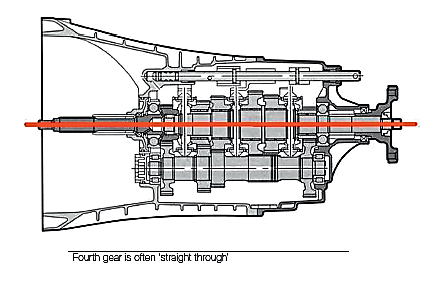

FOURTH GEAR:

- Fourth gear on most rear-wheel drive light vehicles is called direct drive, because there is no gear reduction in the gearbox. In other words, the gear ratio is 1:1.

- The output of the gearbox therefore turns at the same speed as the crankshaft. For front-wheel drive vehicles, the ratio can be 1:1 or slightly different. Most modern light vehicles now have a fifth gear.

- This can be thought of as a kind of overdrive because the output turns more quickly than the engine crankshaft.

- Power comes into the gearbox via the input shaft.

- A gear at the end of this shaft drives a gear on another shaft called the countershaft or layshaft. A number of gears of various sizes are mounted on the layshaft.

- These gears drive other gears on a third motion shaft, also known as the output shaft.