SKEDSOFT

Introduction:

The method of “acceptance sampling” involves the inspection of a small number of units to make decisions about the acceptability of a larger number of units. As for charting methods, the inspected entity might be a service rather than a manufactured unit. For simplicity, the methods will be explained in terms of units. Roaming, working at Bell Laboratories in the 1920s, is credited with proposing the first acceptance sampling methods. Dodge and Roamig (1959) documents much of

the authors’ related contributions.

Acceptance Sampling:

The method of “acceptance sampling” involves the inspection of a small number of units to make decisions about the acceptability of a larger number of units. As for charting methods, the inspected entity might be a service rather than a manufactured unit. For simplicity, the methods will be explained in terms of units. Roamig, working at Bell Laboratories in the 1920s, is credited with proposing the first acceptance sampling methods.

Dodge and Roamig (1959) document much of the authors’ related contributions. Since not all units are inspected in acceptance sampling, acceptance sampling unavoidably involves risks.

The method of “complete inspection” involves using one measurement to evaluate all units relevant to a given situation. Complete inspection might naturally be expected to be associated with reduced or zero risks. Yet often this is a false comparison. Reasons why acceptance sampling might be useful include:

The only trustworthy inspection method is “destructive” testing (Chapter 4). Then complete inspection with nondestructive evaluation is not associated with zero risks and the benefits of inspection are diminishing. Also, complete inspection using destructive testing would result in zero units for sale.

The alternative might be no inspection of the related quality characteristic. The term “quasi-critical characteristics” here refers to KOVs that might be important but might not be important enough for complete inspection. Acceptance sampling permits a measure of control for quasi-critical characteristics.

For these reasons, acceptance sampling can be used as part of virtually any system, even those requiring high levels of quality.

The phrase “acceptance sampling policy” refers to a set of rules for inspection, analysis, and action related to the possible return of units to a supplier or upstream process. Many types of acceptance sampling policies have been proposed in the applied statistics literature. These policies differ by their level of complexity, cost, and risk trade-offs. In this book, only “single sampling” and “double sampling” acceptance sampling policies are presented.

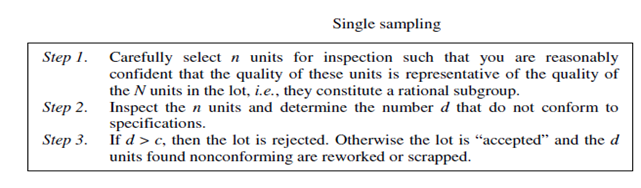

Single Sampling:

Single sampling involves a single batch of inspections followed by a decision about a large number of units. The units inspected must constitute a “rational subgroup”. The symbols used to describe single sampling are:

1.N is the number of units in the full “lot” of all units about which acceptance decisions are being made.

2.n is the number of units inspected in the rational subgroup.

3.c is the maximum number of units that can be found to be nonconforming for the lot to be declared acceptable.

4.d is the number of nonconforming found from inspection of the rational subgroup.

As for control charting processes, there is no universally accepted method for selecting the sample size, n, of the radical subgroup. In single sampling, there is an additional parameter c, which must be chosen by the method user. The primary risk in acceptance sampling can be regarded as accepting lots with large numbers of nonconformities. In general, larger samples sizes, n, and tighter limits on the numbers nonconforming, c, decrease this risk.

Rejection of a lot generally means returning all units to the supplier or upstream sub-system. This return of units often comes with a demand that the responsible people should completely inspect all units and replace nonconforming units with new or reworked units. Note that the same inspections for an acceptance sampling policy might naturally fit into a control plan in the control phase of a six sigma process. One might also chart the resulting data on a p-chart or demerit chart.