SKEDSOFT

Introduction:

Customer-supplier chains based on the JIT philosophy and the regularity of supplies of components and materials is well documented Customer-supplier chains based on technological innovation is less well documented however. More and more technological sophistication is being introduced and issues of compatibility, integration, optimization, flexibility and maintenance are constantly being raised.

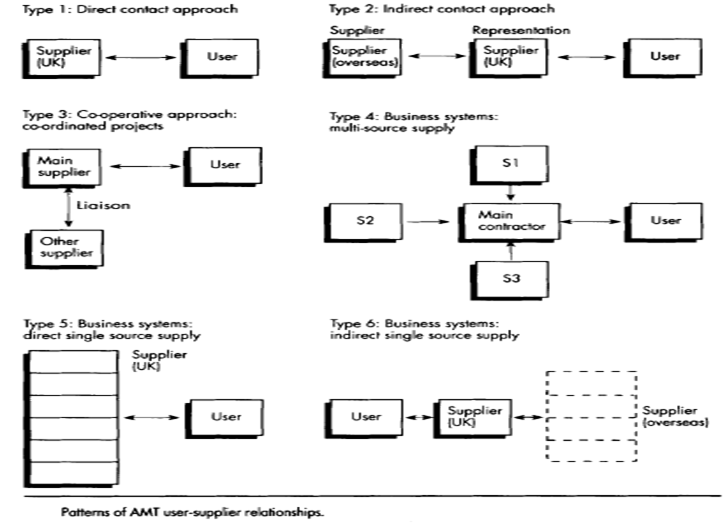

Patterns of AMT user-supplier relationships:

Research carried out by the author has established that there are six possible types of customer-supplier chains based on AMT innovation.

Type I Direct contact approach

This approach is based on a one to one relationship and includes the supply of stand-alone dedicated equipment such as CNC machines. The main characteristics of this type of relationship are the existence of a manufacturing/R&D base in the UK and strong supplier knowledge of the market place. This type only refers to products with a high degree of standardization and communication processes based on simple contacts. Customer involvement in R&D activities tends to be minimal

Type II Indirect contact approach

This is similar to the previous type and is based on supply of foreign built AMT innovation and characterized by the absence of manufacturing/R&D bases in the UK. It includes the supply of stand-alone dedicated equipment such as injection molding machinery and CNC machines. The role of subsidiaries is one of sales and support only.

Type III the co-operative approach

This type generally requires projects to be co-ordinated and usually involves more than one supplier. It was found to be predominant in the computer industry where suppliers of software systems tend to liaise closely with suppliers of hardware equipment. This type of customer-supplier chain is characterized by much more intense communication processes and more customer involvement in R&D activities. Manufacturing/R&D bases are often present.